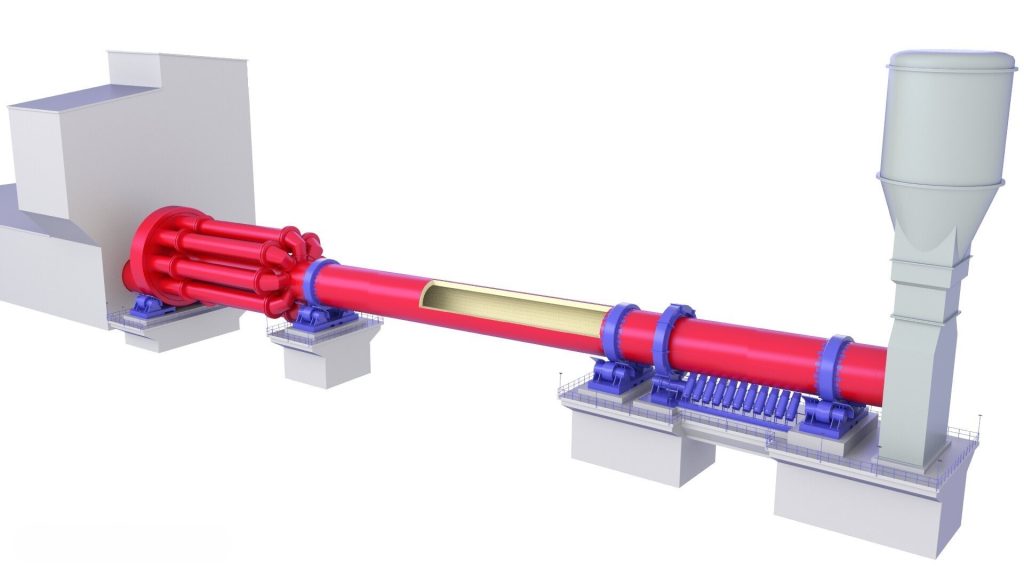

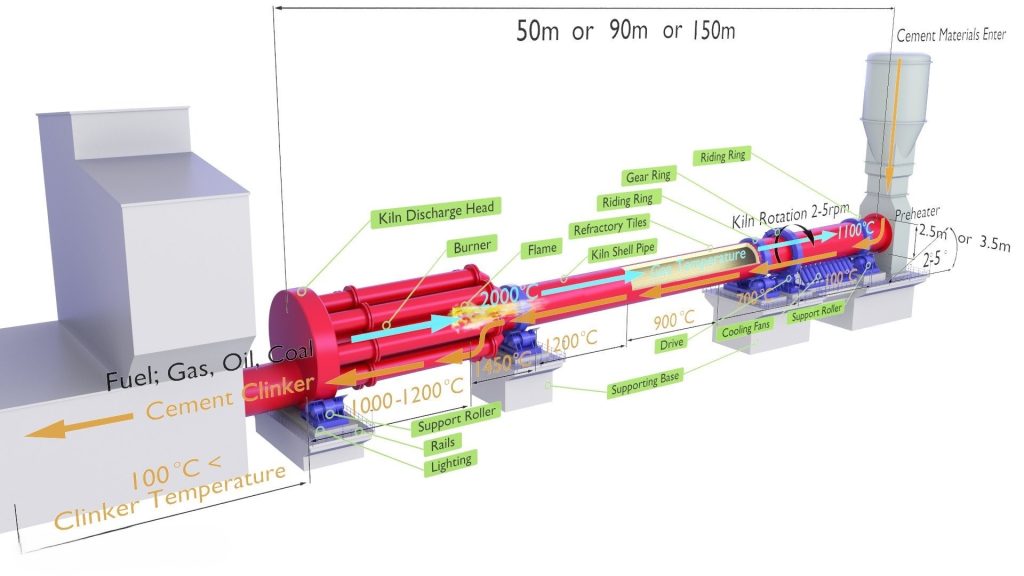

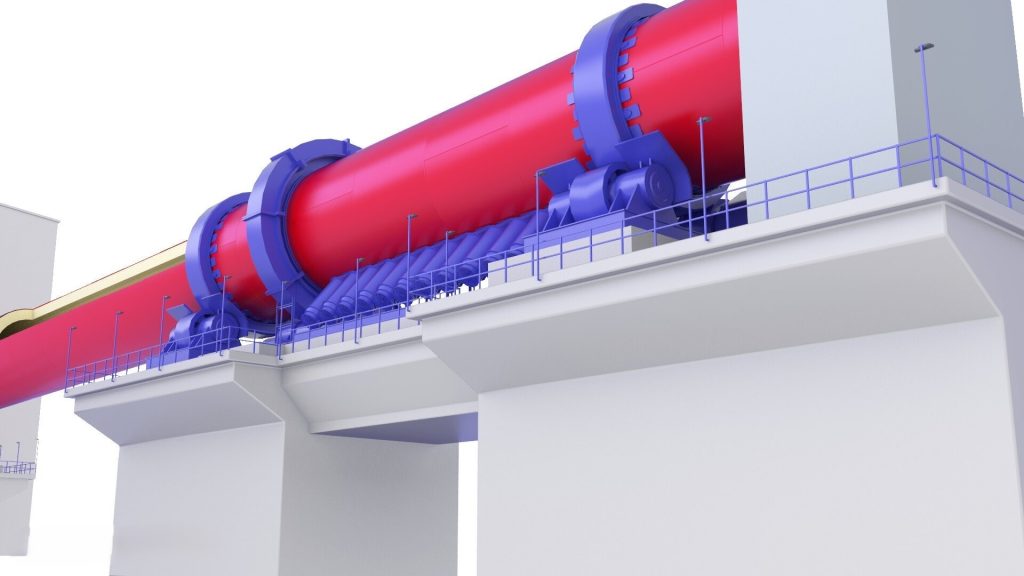

1. Overview of a Cement Rotary Kiln

A cement rotary kiln is a continuous process machine used for heating raw materials (like limestone, clay, and iron ore) to form clinker, the precursor to cement. The process involves:

- Heating raw materials to high temperatures (up to 1450°C).

- Mixing the materials during rotation for even heating.

- Cooling the clinker after formation.

It’s a massive cylindrical device, often inclined slightly to facilitate material flow due to gravity.

2. Detailed Components

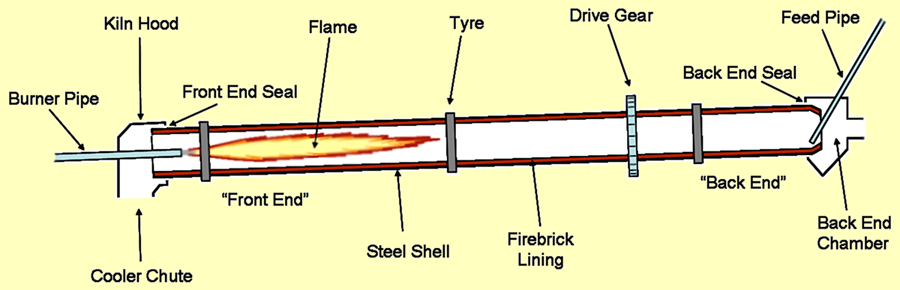

A. Rotary Kiln Shell

- Material: Typically made from mild steel or alloy steel.

- Purpose: Houses the materials and protects the inner workings.

- Design Notes:

- Length-to-diameter ratio (L/D): Usually between 10:1 to 30:1.

- Shell thickness: Typically ranges between 15-50 mm, increasing near the burning zone.

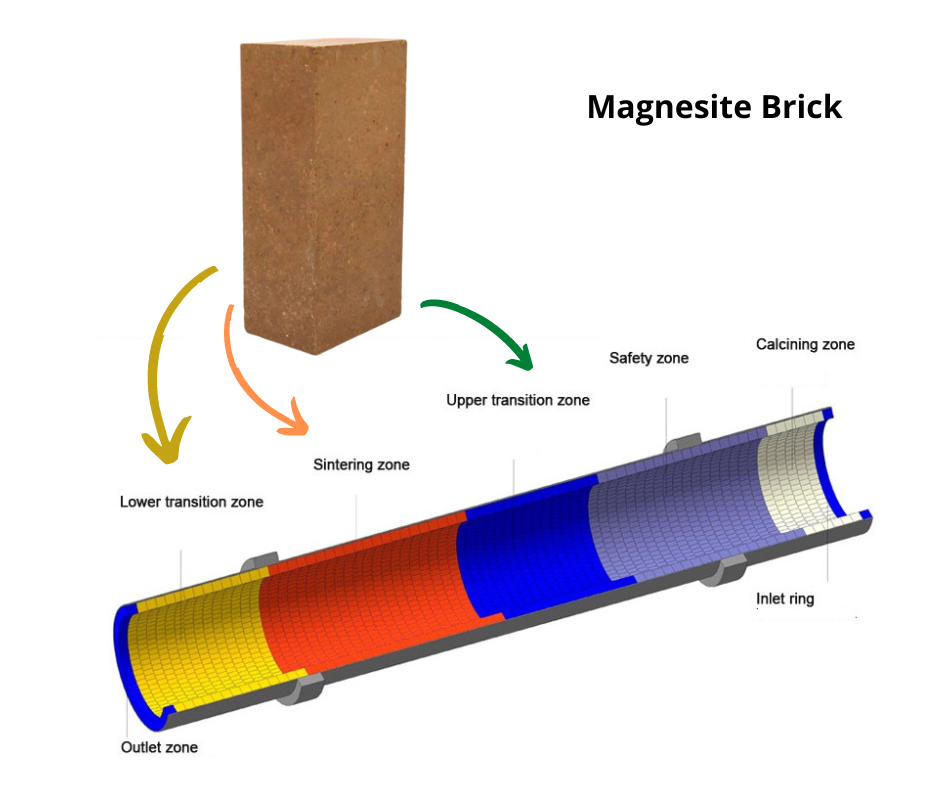

B. Refractory Lining

- Types of Refractories Used:

- Fireclay bricks: For zones under moderate heat (<1000°C).

- High-alumina bricks: For transition zones (1000–1350°C).

- Magnesia bricks: For the burning zone (1350–1450°C), where temperatures and chemical attacks are most intense.

- Refractory castables: For joints and repairs.

- Installation:

- Must be carefully aligned.

- Anchors or mechanical fixings might be used to hold refractory layers.

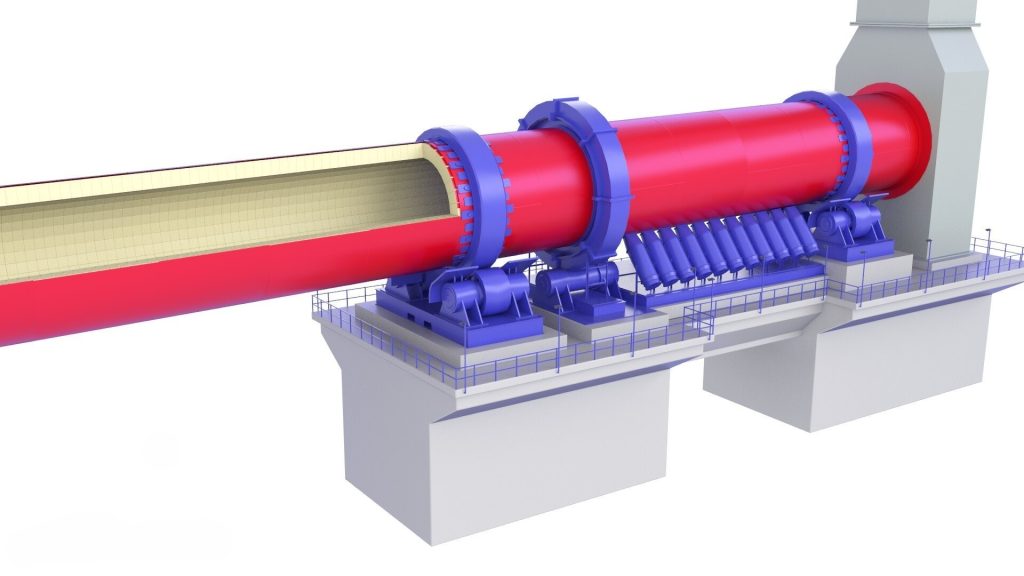

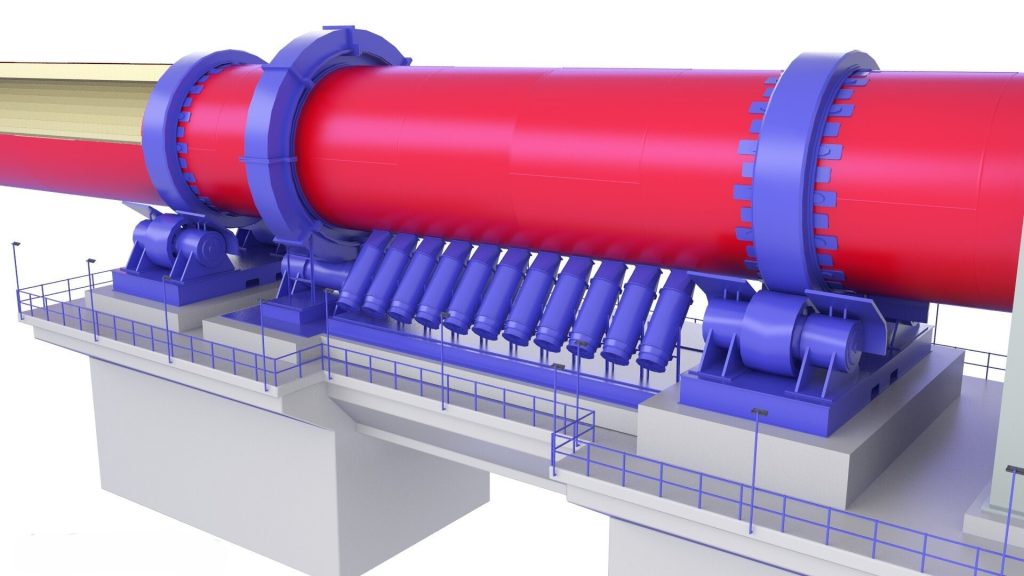

C. Support Rollers and Tyres

- Purpose: Keep the kiln stable and rotating evenly.

- Design Notes:

- Support rollers are made of forged or cast steel.

- Tyres (or riding rings) reduce shell deformation and handle weight distribution.

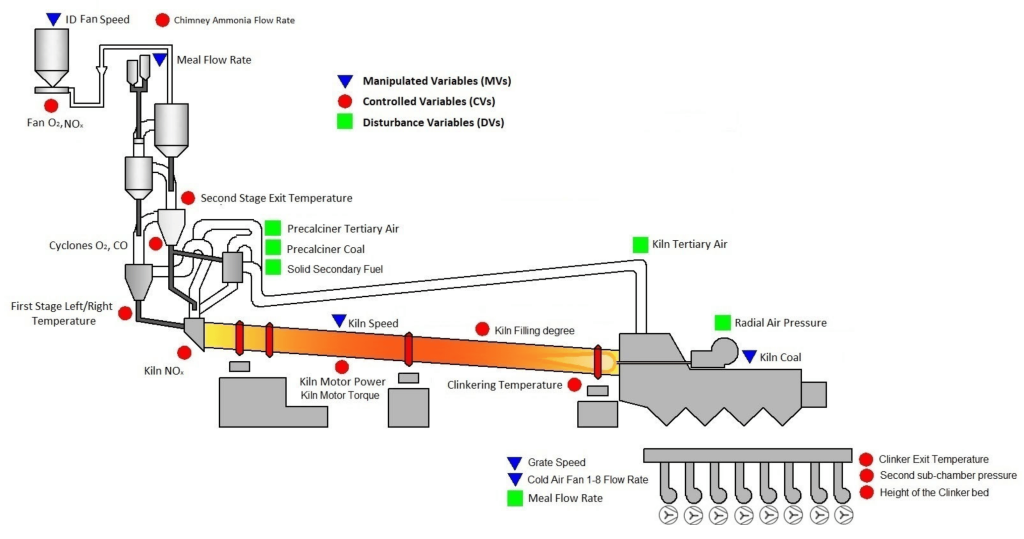

D. Drive Gear and Motor

- Components:

- Gear mechanism: Transmits torque to the kiln.

- Variable speed motor: Controls rotation speed (usually 1-5 RPM).

- Critical Factors:

- Alignment of gears and lubrication are essential to prevent wear.

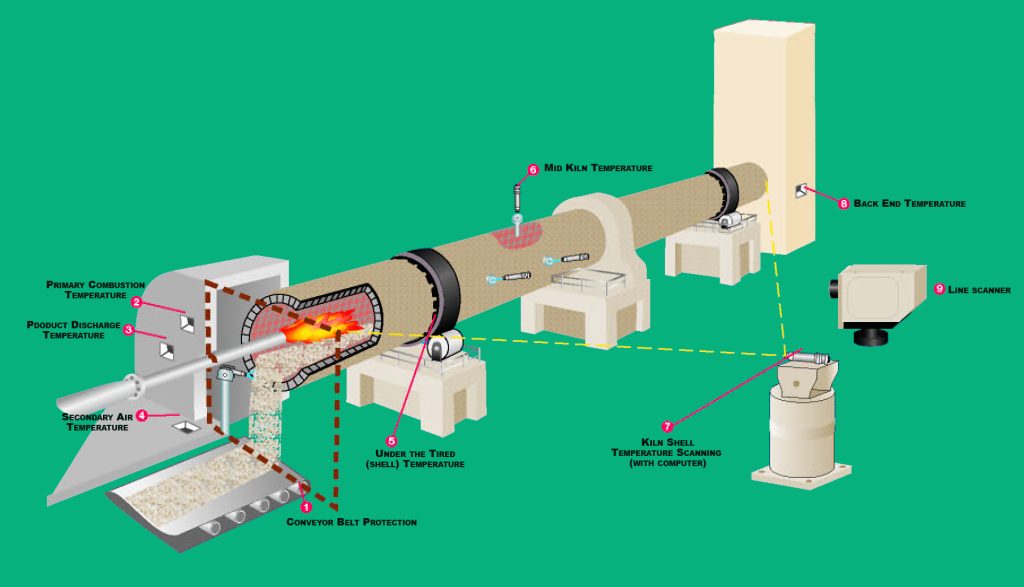

E. Burner System

- Fuel Types: Coal, natural gas, or alternative fuels (e.g., waste-derived fuels).

- Design Notes:

- Modern kilns often use multi-channel burners for precise fuel and air mixing.

- Control systems manage the flame shape and heat distribution.

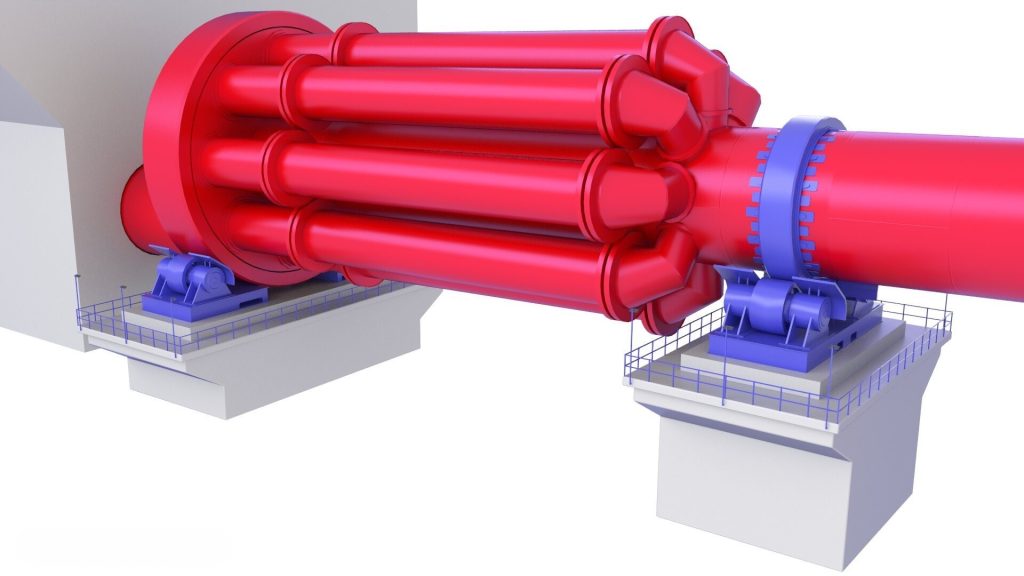

F. Preheater

- Located before the kiln.

- Purpose: Uses hot exhaust gases from the kiln to preheat raw materials.

- Design:

- Cyclones or suspension preheaters improve efficiency.

G. Cooler

- Located after the kiln.

- Purpose: Rapidly cools the clinker to preserve mineral properties.

- Types:

- Grate cooler.

- Rotary cooler.

H. Dust Collection and Pollution Control

- Systems:

- Baghouse filters.

- Electrostatic precipitators.

- Purpose: Captures fine dust particles and reduces emissions.

3. Refractory Lining Zones

The kiln is divided into several temperature zones, each requiring specific refractory materials:

- Inlet Zone (Drying Zone):

- Moderate temperatures (300–900°C).

- Use fireclay bricks or basic refractories.

- Transition Zone:

- Temperatures (900–1350°C).

- Use high-alumina or basic refractories.

- Burning Zone:

- Highest temperatures (1350–1450°C).

- Use magnesia-based bricks for thermal and chemical resistance.

- Cooling Zone:

- Temperatures drop rapidly (<900°C).

- Use fireclay or alumina bricks.

4. Construction Process for Professional-Grade Kiln

Step 1: Design and Planning

- Use CAD software to design the kiln with specifications:

- Calculate dimensions based on production capacity.

- Include all components like preheater, cooler, and burner.

- Perform thermal and mechanical calculations for refractory and shell material.

Step 2: Fabrication

- Kiln Shell:

- Weld steel plates into sections.

- Add reinforcements for structural stability.

- Refractory Lining:

- Install refractories in layers, with precision.

- Ensure tight seals to prevent heat loss.

Step 3: Installation

- Assemble the kiln shell on support rollers.

- Align drive systems and install inlet/outlet seals.

- Attach preheater, cooler, and dust collection systems.

Step 4: Testing

- Perform cold commissioning (without materials) to check rotation, alignment, and seals.

- Conduct hot commissioning to test refractory performance and burner operation.

5. Costs and Challenges

Costs:

- The total cost depends on size and complexity but ranges from $2 million to $20 million for industrial-grade kilns.

- Refractory lining is a significant expense due to material durability.

Challenges:

- High precision is required for alignment.

- Maintenance of refractory materials under thermal and mechanical stress.

- Environmental compliance for emissions.

Recent Comments