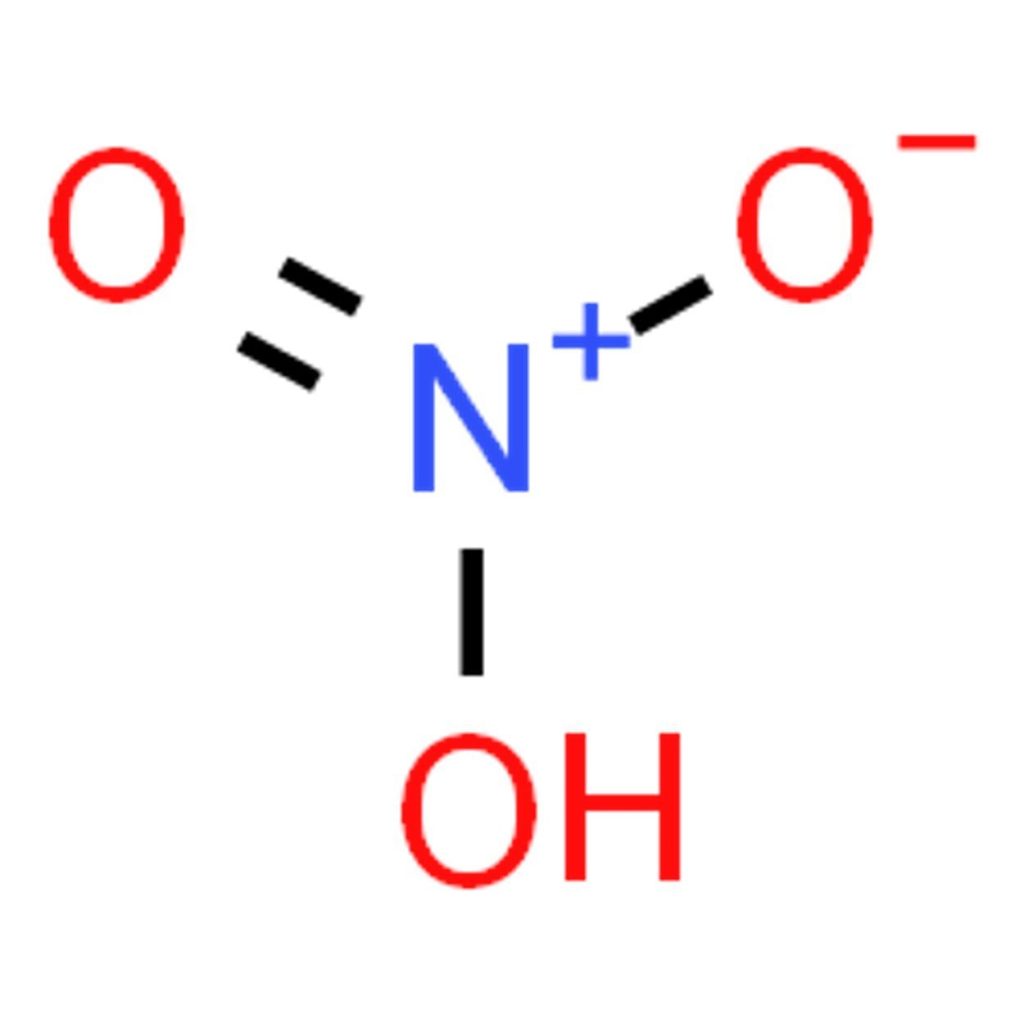

Nitric acid is a highly corrosive and toxic mineral acid with the chemical formula HNO₃. It is a colorless liquid under normal conditions, but older samples can acquire a yellowish tinge due to the decomposition of nitric acid into oxides of nitrogen and water.

Properties of Nitric Acid

- Chemical Properties:

- Molecular Formula: HNO₃

- Molar Mass: 63.01 g/mol

- pH: Aqueous solutions of nitric acid are highly acidic.

- Reactivity: Reacts with metals, nonmetals, and many organic compounds, often resulting in oxidation reactions.

- Physical Properties:

- Appearance: Colorless to pale yellow liquid.

- Density: Approximately 1.51 g/cm³ at 25°C.

- Boiling Point: 83°C (181°F).

- Freezing Point: -42°C (-44°F).

- Concentration:

Nitric acid is available in various concentrations, with the most common being 68% by weight. Concentrated nitric acid (above 86%) is referred to as fuming nitric acid and is further categorized into red and white fuming nitric acid based on its appearance and concentration of nitrogen dioxide.

Uses of Nitric Acid

Nitric acid is an essential industrial chemical with a wide range of applications:

- Fertilizer Production: Used in the production of ammonium nitrate, a key ingredient in fertilizers.

- Explosives Manufacturing: Plays a vital role in making explosives like nitroglycerin and TNT (trinitrotoluene).

- Metal Treatment: Used for etching and cleaning metals, particularly in the electronics and jewelry industries.

- Chemical Synthesis: A precursor for the synthesis of dyes, plastics, and other chemicals.

- Laboratory Applications: Utilized in analytical chemistry for qualitative and quantitative analysis.

Health and Safety Considerations

Nitric acid is a dangerous substance that requires careful handling:

- Corrosive Nature: Can cause severe burns on contact with skin or eyes.

- Toxic Fumes: Inhalation of vapors can irritate or damage the respiratory tract.

- Storage: Should be kept in a cool, well-ventilated area, away from incompatible substances like organic compounds and strong bases.

Environmental Impact

Nitric acid contributes to environmental concerns when improperly managed:

- Acid Rain: Nitrogen oxides, by-products of nitric acid use, can lead to acid rain.

- Water Contamination: Runoff containing nitric acid can harm aquatic ecosystems.

Nitric Acid Production: A Step-by-Step Guide

Nitric acid (HNO₃) is industrially produced using the Ostwald Process, a method developed by Wilhelm Ostwald in 1902. This process involves the catalytic oxidation of ammonia (NH₃) to generate nitric acid. Here’s a detailed explanation of the production process:

Raw Materials Needed

- Ammonia (NH₃): Typically derived from the Haber-Bosch process.

- Oxygen (O₂): Supplied from the air.

- Water (H₂O): Used to absorb nitrogen oxides and form nitric acid.

Steps in the Ostwald Process

Step 1: Catalytic Oxidation of Ammonia

- Ammonia is mixed with air and passed over a platinum-rhodium catalyst at high temperatures (800–950°C).

- This reaction produces nitric oxide (NO) and releases heat (exothermic reaction).

4NH₃ + 5O₂ → 4NO + 6H₂O + Heat

Step 2: Oxidation of Nitric Oxide

- The nitric oxide (NO) produced in the first step is further oxidized by atmospheric oxygen to form nitrogen dioxide (NO₂).

2NO + O₂ → 2NO₂

Step 3: Absorption of Nitrogen Dioxide

- The nitrogen dioxide is absorbed in water to form nitric acid. During this step, some NO₂ converts back into NO, which is recycled into the system.

3NO₂ + H₂O → 2HNO₃ + NO

End Product: This process yields a solution of nitric acid, typically around 68% concentration. To achieve higher concentrations, the solution can be further distilled or treated.

Industrial Equipment Used

- Ammonia Burner: For catalytic oxidation of ammonia.

- Heat Exchangers: To manage and utilize the heat generated during reactions.

- Absorption Towers: For dissolving nitrogen dioxide in water.

- Compressors: To maintain the flow of gases.

Safety Considerations

- High Temperatures: Ensure proper insulation and protective equipment for workers.

- Toxic Gases: Nitrogen oxides (NOx) are harmful; effective scrubbing systems are necessary to reduce emissions.

- Pressure Management: Maintain appropriate pressure levels to avoid system damage.

Small-Scale or Laboratory Production

In a controlled laboratory setting, nitric acid can be produced by reacting a nitrate salt (e.g., potassium nitrate, KNO₃) with concentrated sulfuric acid (H₂SO₄) and then distilling the resulting mixture:

- Mix potassium nitrate and sulfuric acid in a distillation apparatus.

- Heat the mixture gently to produce nitric acid vapors.

- Condense the vapors to collect nitric acid in liquid form.

KNO₃ + H₂SO₄ → KHSO₄ + HNO₃

This method, however, is not suitable for large-scale production due to safety and efficiency concerns.

Exporting nitric acid from human or animal waste (feces) is not a practical or economically viable method for nitric acid production. However, let me break down why this might not work and provide insights on related processes:

Challenges in Producing Nitric Acid from Waste

- Nitrogen Content in Waste:

- Human and animal waste contains nitrogen primarily in the form of urea (CO(NH2)2)(CO(NH₂)₂)(CO(NH2)2), ammonia (NH₃), and organic compounds.

- Converting these nitrogenous compounds into nitric acid would require complex and energy-intensive chemical processes.

- Low Yield:

- The nitrogen content in waste is relatively low compared to other sources like ammonia derived from the Haber-Bosch process.

- Extracting and refining nitrogen from waste would not produce sufficient quantities for large-scale nitric acid production.

- Complex Processing:

- Waste contains various impurities (organic matter, pathogens, etc.) that would require extensive treatment before extraction.

- Advanced biotechnological or chemical methods would be needed to isolate nitrogen, which could then be converted into nitric acid.

- Environmental and Health Risks:

- Handling waste on an industrial scale poses risks of contamination and pollution.

- The process would need strict adherence to environmental regulations.

Alternative Nitrogen Recovery Methods

While directly exporting nitric acid from waste is impractical, there are methods to recover nitrogen from waste, which could indirectly contribute to nitric acid production:

- Ammonia Recovery:

- Wastewater treatment plants sometimes recover ammonia from waste using chemical or biological processes. This ammonia could then be used as a feedstock for nitric acid production via the Ostwald Process.

- Anaerobic Digestion:

- Organic waste can be processed through anaerobic digestion to produce biogas (methane and CO₂) and a nitrogen-rich digestate. The digestate can be processed to recover ammonia.

- Nutrient Recycling:

- Advanced systems are being developed to extract nitrogen and phosphorus from waste streams, which can be utilized in fertilizers or industrial applications.

Conclusion

Exporting nitric acid from waste is not feasible, but waste can serve as a source of nitrogen compounds that might eventually be used to produce nitric acid after extensive processing. For commercial-scale nitric acid production, the established methods like the Ostwald Process using ammonia remain the most efficient and practical.

Recent Comments