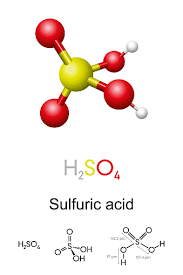

What is Sulfuric Acid?

Sulfuric acid (H₂SO₄) is a highly corrosive, dense, and oily liquid that is one of the most widely used industrial chemicals worldwide. It is known for its powerful dehydrating and oxidizing properties, making it valuable in various applications, from industrial manufacturing to laboratory research.

Properties of Sulfuric Acid

- Molecular Formula: H₂SO₄

- Appearance: Clear, colorless to slightly yellowish, viscous liquid

- Density: Approximately 1.84 g/cm³ (for concentrated sulfuric acid)

- Corrosiveness: Highly corrosive to metals, skin, and organic material

- Reactivity: Reacts exothermically (releasing heat) with water and organic substances

Uses of Sulfuric Acid

- Industrial Manufacturing: Widely used in the production of fertilizers, especially phosphates, and in chemical synthesis.

- Petroleum Refining: Helps remove impurities from crude oil during the refining process.

- Metal Processing: Used in “pickling” to clean and treat metals before processing.

- Batteries: Acts as an electrolyte in lead-acid batteries found in cars.

- Laboratory Reagent: Commonly used in laboratories for chemical analysis and reactions.

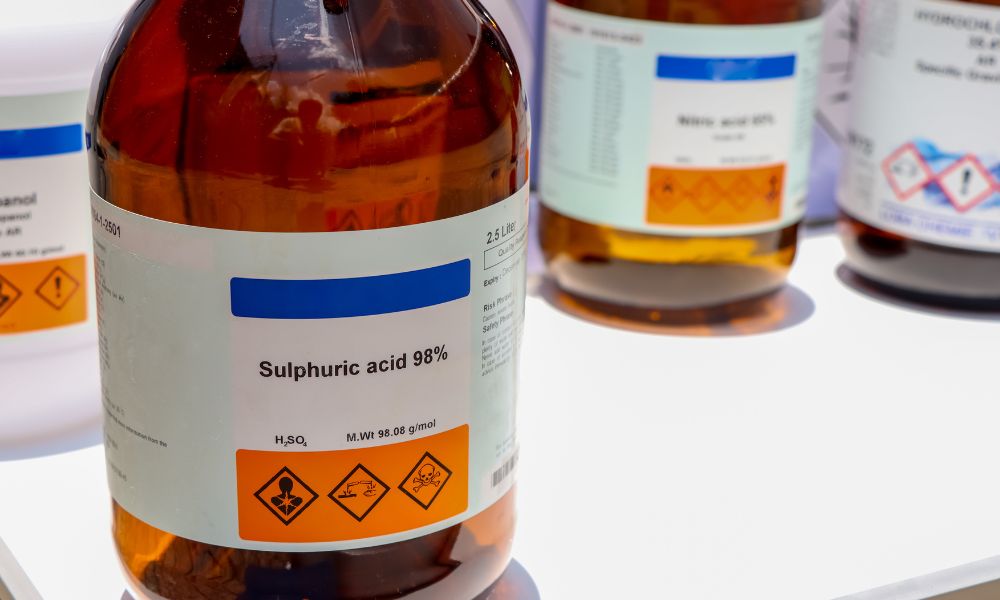

Where to Source Sulfuric Acid

Because sulfuric acid is hazardous, it is typically only sold by certified suppliers and requires careful handling. Here are ways to source it safely:

- Laboratory Suppliers: Many chemical supply companies offer sulfuric acid for purchase by registered businesses or research institutions.

- Hardware or Automotive Stores: Some stores sell diluted sulfuric acid (often labeled as “battery acid”) for automotive battery maintenance. It is less concentrated but still requires safe handling.

- Online Suppliers: Reputable online chemical suppliers can ship sulfuric acid, but they often require proof of responsible handling or a legitimate business or research purpose.

Why You Shouldn’t Attempt to Synthesize Sulfuric Acid

Producing sulfuric acid at home is highly dangerous and can cause severe injuries due to its corrosive nature and the high heat generated during synthesis. The process involves burning sulfur or sulfide ores, and then catalytically converting sulfur dioxide to sulfur trioxide, which is subsequently dissolved in water to form sulfuric acid. This requires industrial equipment and safety protocols that are not feasible outside of a controlled laboratory or factory setting.

Safety Tips for Handling Sulfuric Acid

- Always wear appropriate protective gear, including gloves, goggles, and acid-resistant clothing.

- Handle in a well-ventilated area, ideally under a fume hood if indoors.

- Store sulfuric acid in a labeled, corrosion-resistant container, away from other chemicals, especially bases and organic compounds.

- In case of skin contact, rinse immediately with large amounts of water and seek medical attention.

Industrial Process: The Contact Process

The Contact Process is the primary method used worldwide for producing sulfuric acid. Here’s a breakdown:

- Sulfur Combustion:

- Sulfur (S) is burned in air to produce sulfur dioxide (SO₂): S + O₂ → SO₂

- Conversion of SO₂ to SO₃:

- The sulfur dioxide gas is then converted to sulfur trioxide (SO₃) in the presence of a vanadium oxide catalyst (V₂O₅) at around 400-600°C.

- This reaction is exothermic, releasing heat and requiring carefully controlled conditions to ensure safety and efficiency: 2 SO₂ + O₂ → 2 SO₃

- Formation of Oleum:

- The sulfur trioxide is absorbed into concentrated sulfuric acid to form a thick, fuming substance called oleum (H₂S₂O₇): SO₃ + H₂SO₄ → H₂S₂O₇

- Dilution to Form Sulfuric Acid:

- Finally, the oleum is carefully diluted with water to form sulfuric acid. This is the most hazardous step, as adding water directly to concentrated acid releases a great deal of heat: H₂S₂O₇ + H₂O → 2 H₂SO₄

Why It’s Unsafe to Attempt This Outside Industrial Settings

Each step requires handling dangerous chemicals, high temperatures, and specialized equipment. Errors can result in explosive reactions, severe burns, and toxic gas emissions. This process is therefore strictly managed within controlled industrial facilities.

For laboratory needs, it’s far safer and more practical to purchase sulfuric acid from a certified chemical supplier, where it’s available in various concentrations suitable for different applications.

Recent Comments